Cultured foods—also known as cell-based foods—are expected to turn our global food system as we know it on its head.

In fact, the cultured meat market is estimated to reach an eye-watering $25 billion by 2030 according to McKinsey, but only if it can overcome hurdles such as price parity and consumer acceptance. To do so, significant innovation in the science behind these products will be crucial for the industry’s growth.

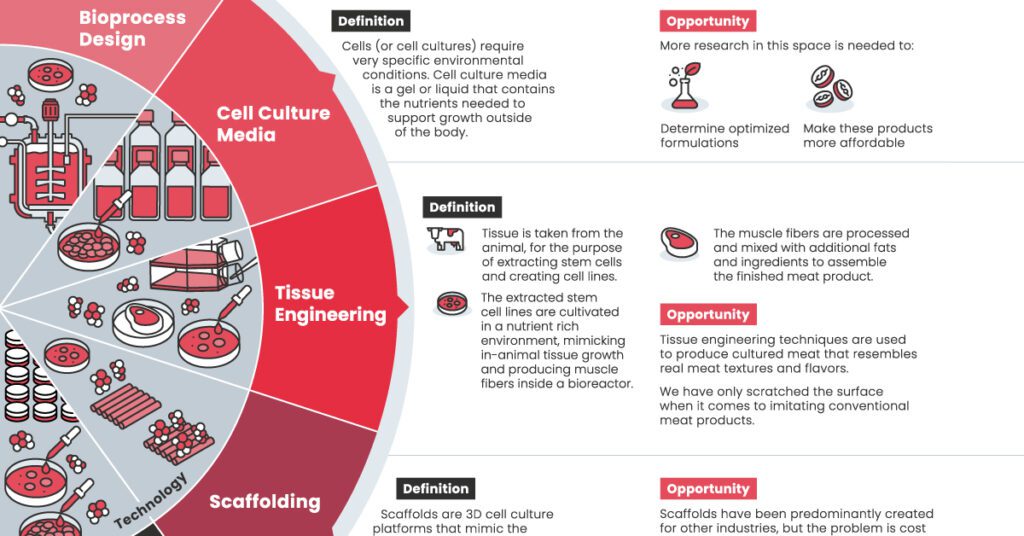

In the graphic above from our sponsor CULT Food Science, we provide a visual overview of some of the technologies behind the creation of cultured meat products.

What is Cultured Meat?

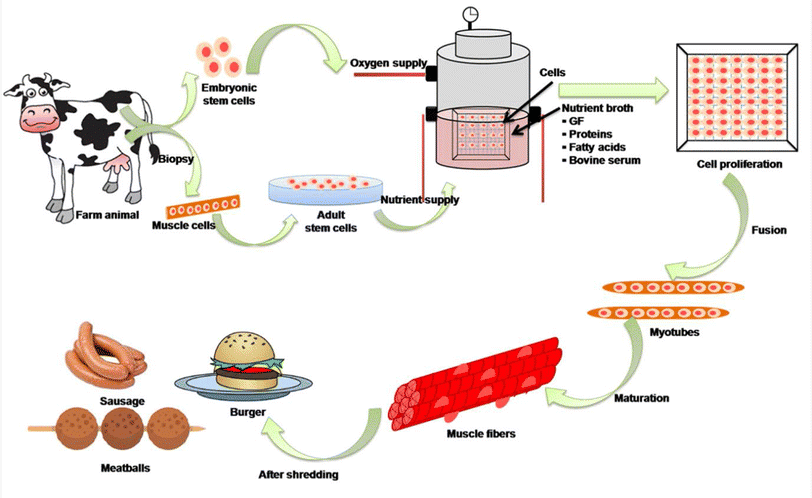

To start, cultured meat is defined as a genuine animal meat product that is created by cultivating animal cells in a controlled lab environment—eliminating the need to farm animals for food almost entirely.

Because cultured meat is made of the same cell types and structure found in animal tissue, the sensory and nutritional profiles are like-for-like. Let’s dive into how these products are made.

The Science and Technology Behind Cultured Meat

The main challenge facing the cultured meat market is producing products at scale. But thanks to the vast amount of research in the stem cell biology space, the science behind cultured foods is not entirely new.

Given that we are in the very early days of applying these learnings to producing food products, those looking to invest in companies contributing to the industry’s growth stand to benefit. Here is an overview of some of the technologies that underpin the industry that you should know:

1. Bioprocess Design

This is the process of using living cells and their components to create new products. According to experts like the Good Food Institute, bioprocess design holds the key to unlocking cultured meat production at scale.

Specifically, innovation in bioreactor (where the cells grow) design represents a massive opportunity for companies and investors alike.

2. Tissue Engineering

Tissue engineering techniques are used to produce cultured meat that resembles real meat textures and flavors. The first step is taking tissue from the animal for the purpose of extracting stem cells and creating cell lines.

The extracted stem cell lines are then cultivated in a nutrient-rich environment, mimicking in-animal tissue growth and producing muscle fibers inside a bioreactor. The muscle fibers are processed and mixed with additional fats and ingredients to assemble the finished meat product.

3. Cell Lines

Cell lines refer to the different types of cells that can be propagated repeatedly and sometimes indefinitely.

Access to cell lines is a major challenge facing the industry today and is an area that requires significantly more research. This is because there is not just one cell type that can be used in cellular agriculture to produce cultured food products.

4. Cell Culture Media

Cells (or cell cultures) require very specific environmental conditions. Cell culture media is a gel or liquid that contains the nutrients needed to support growth outside of the body.

More research in this space is needed to determine optimized formulations and make these products more affordable.

5. Scaffolding

Scaffolds are 3D cell culture platforms that mimic the structure of complex biological tissues, such as skeletal muscle. These platforms can be created through the use of 3D Bioprinting.

Scaffolds are predominantly made up of collagen and gelatin. The problem is these are both animal-derived ingredients that defeat the purpose of cell-based products. Therefore, more sustainable plant-derived options are also being explored.

Investing in the Future of Cultured Meat

CULT Food Science is an innovative investment platform advancing the technology behind the future of food with an exclusive focus on cultured meat, cultured dairy, and cell-based foods.

The company’s global portfolio spans four continents and includes exposure to a diverse pipeline:

- Cell lines

- End products

- Scaffolding technology

- Growth medium

- Intellectual property