Quotes from Rest of World, 19 June, 2024

Nestled in the chic Dempsey Hill area of Singapore, Huber’s Butchery has become a destination for discerning customers seeking a variety of gourmet products. Recently, the establishment has expanded its offerings to include a pioneering product: lab-grown shredded chicken. This marks a groundbreaking moment as it represents the first instance globally where consumers can purchase lab-grown meat directly from a retail environment, according to the product’s creators.

Lab-grown meat, a novel culinary innovation, has graced select dining establishments in Singapore and the United States for some time now. The introduction of Good Meat 3 by the Californian food tech company Eat Just at Huber’s marks a significant milestone for this sector, which has recently experienced a downturn. The sector is witnessing waning investor enthusiasm, and regulatory hurdles have emerged, with lab-grown meat facing prohibitions in Italy, as well as in the American states of Alabama and Florida.

The initiation of retail sales marks a significant achievement not only for the enterprise but also represents a pivotal moment for the industry of lab-grown meat, as expressed by Josh Tetrick, the co-founder and CEO of Eat Just, in a conversation with Rest of World. The company’s latest offering incorporates a mere 3% of lab-grown chicken, a strategy aimed at setting an affordable price to encourage broader consumer sampling, he explained. Tetrick also highlighted Singapore’s consistent receptivity to innovative food technologies and other advancements, deeming it an ideal environment for introducing groundbreaking products such as lab-grown meats.

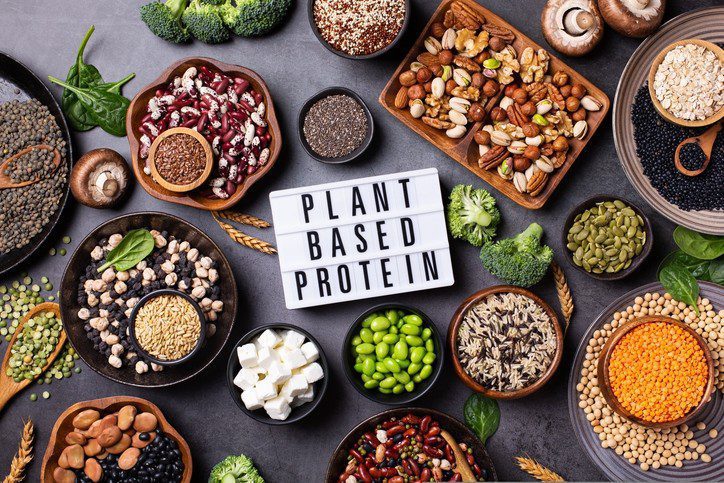

In contrast to the widespread adoption of plant-derived meat alternatives championed by companies like Impossible Foods and Beyond Meat, lab-grown meat has yet to achieve a significant breakthrough, despite the initial surge of excitement surrounding its development.

The methodologies of tissue engineering, which form the foundation of lab-grown meat, have been historically applied in the development of pharmaceuticals and immunizations. This process involves cultivating animal cells in controlled laboratory environments to form fats and tissues, which are then converted into an array of proteins. The clear benefits of this approach include a reduction in the requirement for land and water resources, as well as a potential decrease in the emission of greenhouse gases. However, the production of lab-grown meat presents economic challenges due to its high costs and difficulties in expanding production, which has led to fluctuating levels of investment interest.

Over the past ten years, the global investment in lab-grown meat, exceeding $3 billion, represents just a small portion of the funds allocated to other technological sectors like renewable energy, which share a common goal of emission reduction. Mirte Gosker, the managing director at the Good Food Institute Asia Pacific, a nonprofit organization, expressed to Rest of World that the primary challenge hindering lab-grown meat from becoming mainstream is the widespread lack of investment in research and development, as well as in the necessary production infrastructure, particularly by governmental bodies.

Singapore embarked on a significant initiative in March 2019, aiming to boost its self-sufficiency in food production. The nation’s ambitious “30 by 30” goal is to locally produce 30% of its nutritional requirements by the year 2030, a substantial increase from the previous 10%. Central to this endeavor is the development of alternative protein sources. According to Gosker, the scope of Singapore’s strategy extends further than just fulfilling local demand.

Despite being a small country and having natural resource constraints, Singapore is not positioned to provide sustenance for the global population on its own. However, it can potentially become a global hub where international enterprises can collaborate with leading research institutions and food technology allies. This collaboration aims to enhance their product recipes, streamline production methods, and investigate innovative approaches and components that could contribute to a reduction in expenses.