To reuse chicken farming waste, Nanyang Technological University, Singapore (NTU Singapore) together with the Leong Hup Singapore Pte Ltd have jointly developed procedures. One of the important breakthroughs is replacing synthetic polymers, which are derived from petroleum oil and whose manufacturing, usage, and disposal create greenhouse gas emissions, with egg trays made of chicken feather keratin.

“The project has clearly demonstrated that feathers can no longer be viewed as a waste product. Instead, they should be seen as a source of valuable raw materials and an essential component to the circular economy, in which raw materials, components and products lose their value as little as possible,” says Professor William Chen, Director of NTU’s Food Science and Technology Programme, co-lead of the industry collaboration.

He added that using chicken feather fibres in composite materials is a new source of materials that are cost-effective, environmentally friendly, and recyclable. Meanwhile, repurposing poultry blood to cultivate cell-based chicken meat could be a step toward reducing the food industry’s carbon footprint.

Every year, billions of kilogrammes of unwanted chicken feathers are discarded by poultry processing plants. This by-product is typically buried in landfills or incinerated, both of which contribute to greenhouse gas emissions.

Because the material made from chicken feathers is more durable and flexible than those made from synthetic polymers derived from petroleum oil, the newly discovered method would be a greener alternative.

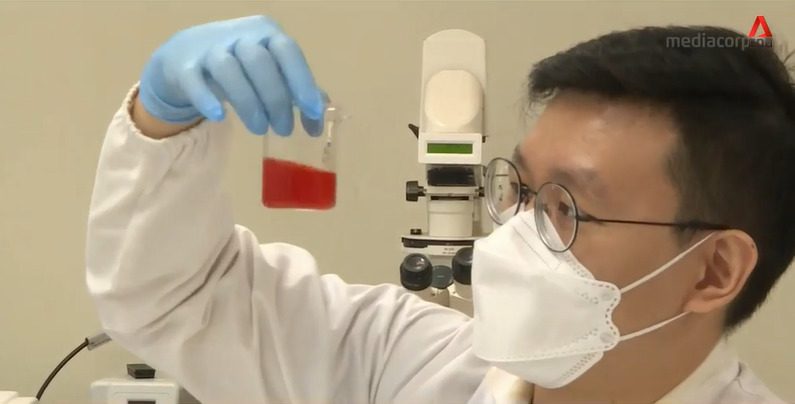

Another breakthrough was the successful conversion of biological waste such as blood and bones, into an alternative and cost-effective culture medium that could be used to cultivate cell-based meat. Poultry blood and by-products of animal and food processing are high in organic matter and contain high concentrations of growth factors and other nutrients. Because organic waste from poultry processing contains amino acids, vitamins, glucose, inorganic salts, and growth factors, it is ideal for cell culture mediums used to cultivate cell-based meats.

The NTU scientists were also successful in extracting those nutrients and developing a solution capable of growing animal cells for lab-grown meat. Recent studies have also shown that serum derived from poultry blood and the biological matter has the potential to replace foetal bovine serum as a medium for cultivating cell-based meat because it contains comparable concentrations of growth factors and other nutrients.

Singapore’s food security goals may include alternative proteins

Meanwhile, the Singapore Food Story R&D Programme has been funding research projects in sustainable urban food production, future foods, and food safety science and innovation since 2021.

According to Dr Andrew Wan, Principal Investigator at the Singapore Institute of Food and Biotechnology Innovation (SIFBI), this grant will encourage researchers, technology providers, and potential adopters to collaborate on innovative solutions for the alternative protein industries.

Scientists at A*STAR’s SIFBI, in collaboration with other research institutions, are developing new animal-free cell-growing technologies that could eventually lower the cost of cultivated meat. Texturisation methods are being used by food process engineers to transform proteins from alternative sources into fibrous products with a meat-like appearance and mouthfeel.

Efforts are being made to quantify and thus improve the digestibility, nutritional, and sensorial properties of proteins. All of this is done with the goal of matching, if not exceeding, the properties of what we call meat.

Singapore has made significant progress, particularly in the cultivation of meat. After becoming the world’s first country to grant regulatory approval to a cultivated meat product, Good Meat, it would now house the largest facility in Asia to produce the same. Earlier this month, Good Meat held a ground-breaking ceremony for its S$61 million R&D and manufacturing facility at Bedok Food City.