BY JOHN REISS

You may have heard about cultivated meat—genuine meat developed from cells of living animals—and its potential to disrupt the traditional way meats are produced. It may be easy to dismiss cultivated meats as a fad; however, well over $2 billion in venture capital has poured into this emerging technology in just ten years.

Big players, from billionaires like Bill Gates (Microsoft) to Michelin-starred chefs (José Andrés) and celebrities (Leonardo DiCaprio), have thrown their weight and money into it. Some of the world’s largest meat companies, including Tyson, Cargill, and JBS, have also invested in its potential. Although currently only legal to sell in Singapore, there is growing acceptance that this technology is close to realizing full-scale production and may start selling in the United States soon.

So why should consumers care about a product currently unavailable for sale? One big reason is growth in the world population, which is projected to reach about 9.7 billion people by 2050. Since most people are meat eaters, about 90% in the United States and 86% worldwide, population growth will place added pressure on the food supply chain.

Environmental factors also play a big part in the rationale for cultivated meats. Traditional animal farming methods rely on large amounts of fresh water and land resources, adding an estimated 14.5% of greenhouse gases into the atmosphere. The Good Food Institute (GFI), a leading advocate for both cultivated meat and vegan meat replacements, claims cultivated meat can reduce emissions by over 90% and use as much as 95% less land and close to 80% less water than conventional beef.

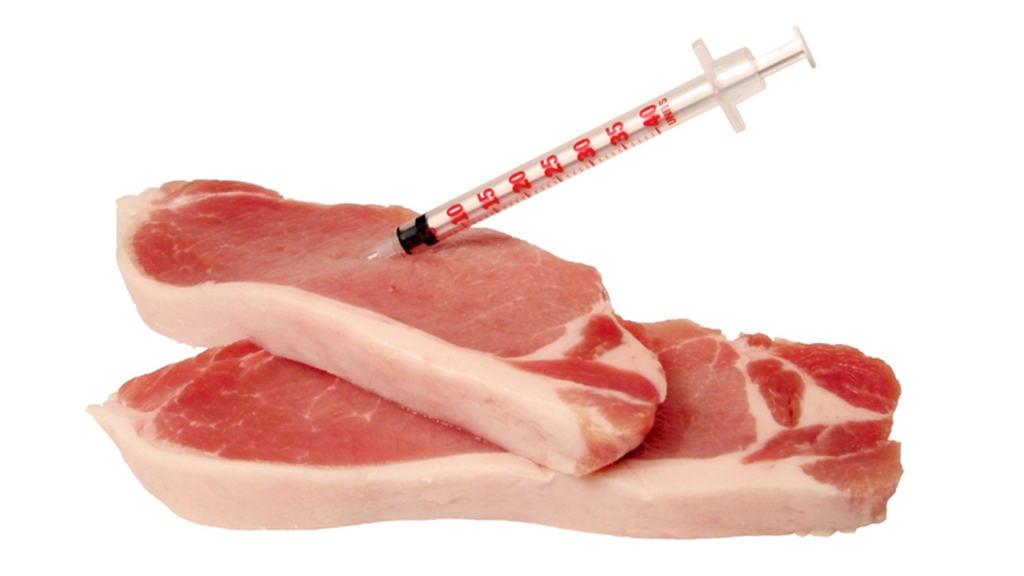

Equally important, cultivated meat eliminates foodborne pathogens such as E. coli and Salmonella, common bacterial problems deriving from animal processing that infect humans and create epidemics and pandemics. In addition to ending these pathogens, lab-grown meat also eliminates the collateral use of antibiotics in livestock farming.

What Is Cultivated Meat?

Various words have been used to describe cultivated meat products, including “lab grown,” “clean meat” or “cultured meat.” “Cultivated meat,” however, is a term the industry seems to lean toward. The idea of using science for meat production took off after Dutch professor Mark Post at the Maastricht University presented the world’s first cultivated hamburger in 2013. Its price tag: about $330,000. In the 10 years since then, rapid breakthroughs have lowered the cost considerably, making the product more commercially viable today.

In the process of cultivating meat, according to the GFI, stem cells are taken from biopsies of live animals. Then, they are grown in bioreactors while fed essential nutrients such as amino acids, glucose, and vitamins. The process is estimated to take two to eight weeks, depending on the type of meat—substantially less time than producing traditional farmed beef, which requires one to two years.

Companies in the cultivated meat industry have pilot-tested cultivated meat, poultry, seafood, dairy, and egg products, and are getting ready for full-scale production. Products currently under development range from familiar beef and chicken to exotic offerings like sushi-grade tuna, lobster, and foie gras (fattened duck).

Ground meat products like nuggets or burgers are the simplest to cultivate. For whole meat cuts, a three-dimensional structure, called scaffolding, is layered with cultivated fats and connective tissues, resulting in the desired shape and texture of steaks and fillets. As with conventional 3D printing, the product is printed in a layering process and then matures and grows into something we would recognize as, say, a steak.

** Click here to read the full-text **